Types of Thermal Ribbons

Wax

Wax ribbons are the most common type of thermal transfer ribbon. They have a very low resin content and are comprised mostly of wax. This gives them a low melting point, which makes the print lighter and less durable than other ribbon types. They are, however, the cheapest ribbon option.

Wax ribbons are usually printed on uncoated paper label stock, although they can be used on coated paper and some synthetic stocks as well. They are ideal for paper labels, including retail, shipping and warehouse labels.

Wax/Resin

Wax/resin ribbons, as the name implies, are made of a blend of wax and resin. They are significantly more durable than wax ribbons and are able to resist higher temperatures, exposure to chemicals and constant handling. They are, however, more expensive as well.

Wax/resin ribbons work well on a wide variety of label stock types, including coated and uncoated paper and synthetic label materials. They are ideal for barcode labels, shipping labels and pharmaceutical labels.

Resin

Resin ribbons are the most durable and most expensive of the thermal transfer ribbon types. They have a very high melting point, meaning that they can withstand extreme temperatures, chemicals, water and heavy handling.

Resin ribbons are printed on synthetic materials, such as polyester and polypropylene. They should only be used for jobs that require extreme durability, such as labeling for chemicals and sensitive medical applications.

Near-Edge

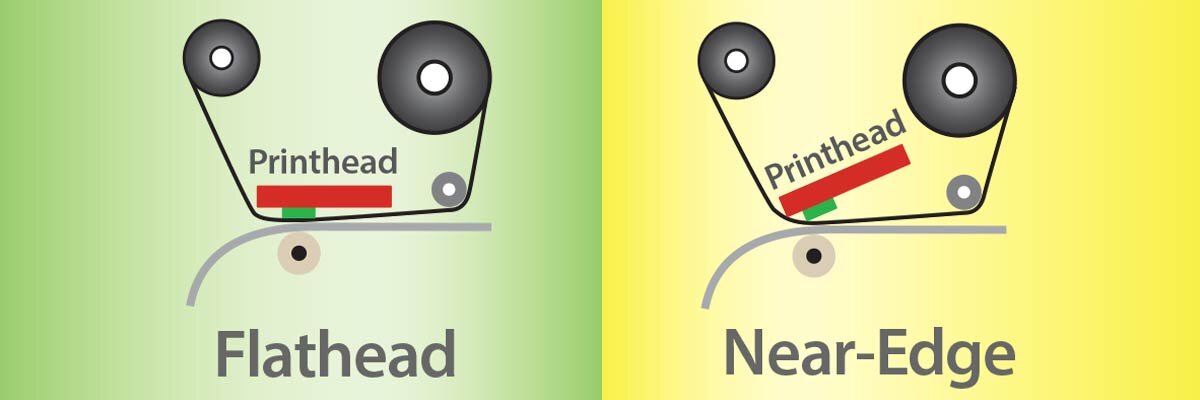

Most thermal transfer printing uses a method called flathead printing. With this, the printhead is held in a horizontal position against the label stock. With near-edge printing, the printhead meets the label at an angle. For this printing method, you need near-edge ribbons.

Near-edge ribbons allow for faster, edge-to-edge printing, as well as thicker label stock. They can be used on both paper and synthetic labels and are often used to timestamp food packaging.